Main advantages of the PBS-A device

To provide an effective, clean, secure and reliable solution gives PBS-A high added value. It proposes an adaptive device (depending on special needs) that solves a number of current battery problems. In general, four topics are detailed below which the PBS-A system provides a better result for.

Ecological transition

For several years now, national and international organizations have been working to promote laws and regulations based on the reduction of pollution in general. Regulations to reduce emissions of CO2, regulations to support the production of renewable energies or the establishment of countless agreements between governments and companies to establish pollution limits are some of the most well-known actions in this area.

In our area, both the European Union and ECHA and other multinational agencies or companies are committed to the gradual reduction of lead acid in industrial components, and more specifically in batteries intended for the automotive sector. In the long run, it is planned to reduce the amounts of lead used in manufacturing until it is banned, thereby eliminating lead from batteries intended for the automotive industry.

It is true that as a result of technological progress and economic investment, batteries have been produced with other kinds of compositions, as well as their advantages and disadvantages. However, lead acid batteries are marketed in large volumes and, although almost completely recycled, remain a harmful and pollutant source for our health.

PBS-A is an indispensable ally in this ecological transition we are experiencing and presents a solution that is perfectly suited to these demands. Besides its advantages in weight, size, capacity, and others. The result is an improved, more efficient and sustainable product that reduces the chemical part of the battery by replacing it with electronics.

Ecological transition

For several years now, national and international organizations have been working to promote laws and regulations based on the reduction of pollution in general. Regulations to reduce emissions of CO2, regulations to support the production of renewable energies or the establishment of countless agreements between governments and companies to establish pollution limits are some of the most well-known actions in this area.

In our area, both the European Union and ECHA and other multinational agencies or companies are committed to the gradual reduction of lead acid in industrial components, and more specifically in batteries intended for the automotive sector. In the long run, it is planned to reduce the amounts of lead used in manufacturing until it is banned, thereby eliminating lead from batteries intended for the automotive industry.

It is true that as a result of technological progress and economic investment, batteries have been produced with other kinds of compositions, as well as their advantages and disadvantages. However, lead acid batteries are marketed in large volumes and, although almost completely recycled, remain a harmful and pollutant source for our health.

PBS-A is an indispensable ally in this ecological transition we are experiencing and presents a solution that is perfectly suited to these demands. Besides its advantages in weight, size, capacity, and others. The result is an improved, more efficient and sustainable product that reduces the chemical part of the battery by replacing it with electronics.

Battery temperature

The most common problem with acid lead batteries is the temperature at which they work. They are known to work efficiently at room temperature, but approaching extreme temperatures (low or high) produces unusual performance. At minus 20°C, the battery delivers only 60% of the energy that can be supplied under normal conditions, greatly reducing its useful life due to sulfation and oxidation. Charging and discharging above 45°C can reduce its useful life by 5 times because of the high battery requirements needed.

The same is true of lithium ion batteries in electric vehicles. Their functioning/performance varies depending on their working temperature, whether they are very high or very low. At extreme ambient temperatures, (when using air conditioning or heating), we must add the energy demand that the driver will need. All of this consumes the energy accumulated in these batteries faster, so it is essential to work at the appropriate temperature range so as not to reduce their useful life.

According to a study of this area, the optimal working temperature of a battery of lithium ions is between -10ºC and 30ºC. It should be borne in mind that room temperature also determines the temperature of operation and reduces the capacity to load/charge in medium and long term.

As in acid lead batteries, heat increases its storage capacity. Up to 45°C, this capacity increases linearly and a higher percentage of energy can be retained if the ambient temperature is also high. But this extreme temperature gain greatly reduces the lifespan of lithium ion battery . The cold affects its operation differently from the heat. It reduces performance and recharge capacity at values close to 20% below -5ºC.

Charging and unloading batteries in optimum conditions is an utopia. In most cases, they provide huge peaks of energy and work at temperatures closer to the extremes than in the optimal range. So the PBS-A system is a perfect opportunity to eliminate this problem. The technology, based on supercapacitors makes it possible to operate efficiently at a temperature range of -40ºC to 60ºC, extending the battery's useful life because it will not provide a high peak of intensity (such as when starting) at extreme temperatures.

Battery temperature

The most common problem with acid lead batteries is the temperature at which they work. They are known to work efficiently at room temperature, but approaching extreme temperatures (low or high) produces unusual performance. At minus 20°C, the battery delivers only 60% of the energy that can be supplied under normal conditions, greatly reducing its useful life due to sulfation and oxidation. Charging and discharging above 45°C can reduce its useful life by 5 times because of the high battery requirements needed.

The same is true of lithium ion batteries in electric vehicles. Their functioning/performance varies depending on their working temperature, whether they are very high or very low. At extreme ambient temperatures, (when using air conditioning or heating), we must add the energy demand that the driver will need. All of this consumes the energy accumulated in these batteries faster, so it is essential to work at the appropriate temperature range so as not to reduce their useful life.

According to a study of this area, the optimal working temperature of a battery of lithium ions is between -10ºC and 30ºC. It should be borne in mind that room temperature also determines the temperature of operation and reduces the capacity to load/charge in medium and long term.

As in acid lead batteries, heat increases its storage capacity. Up to 45°C, this capacity increases linearly and a higher percentage of energy can be retained if the ambient temperature is also high. But this extreme temperature gain greatly reduces the lifespan of lithium ion battery . The cold affects its operation differently from the heat. It reduces performance and recharge capacity at values close to 20% below -5ºC.

Charging and unloading batteries in optimum conditions is an utopia. In most cases, they provide huge peaks of energy and work at temperatures closer to the extremes than in the optimal range. So the PBS-A system is a perfect opportunity to eliminate this problem. The technology, based on supercapacitors makes it possible to operate efficiently at a temperature range of -40ºC to 60ºC, extending the battery's useful life because it will not provide a high peak of intensity (such as when starting) at extreme temperatures.

Safety

Another of the most important advantages of batteries with PBS-A systems is safety. Innovative technology ensures safe use, providing high reliability to the entire system. The most significant safety features are:

It extrapolates the Run-Flat concept of tyres. Even if the battery is not fully operational, the PBS-A device is capable of running the vehicle for several days.

In military, law enforcement, or private security vehicles, an additional function is included. In the event of a catastrophic failure or emergency situation, it adds an internal panic button, which will start the vehicle in a matter of moments without leaving the vehicle and ensure its operation (even if the chemical energy source is completely unusable).

Even if the factory battery fails, the device keeps the vehicle's electrical and electronic systems operational.

Detects anomalies prior to a failure or problem thanks to the constant monitoring of the vehicle's electrical and electronic parameters. Allows preventive maintenance before a breakdown occurs.

The PBS-A system can detect, thanks to parameter monitoring, whether the driver is driving properly.

Automatically cuts off the current at the PBS-A system terminals in case of an accident.

It is possible to limit the operation of the system from a control center in a certain period of time by a specific geographical area. If the vehicle attempts to leave the delimited area, the control center will shut down the system and the vehicle will stop operating.

Communication via smartphone is allowed in order to manually activate some functions of the PBS-A system, such as real-time parameter display or automatic vehicle locking.

As can be seen, the device combines its electronics and programming so that security is above everything else. There will be no more headaches for a battery in bad condition or unexpected failures. With PBS-A, your safety is guaranteed.

Safety

Another of the most important advantages of batteries with PBS-A systems is safety. Innovative technology ensures safe use, providing high reliability to the entire system. The most significant safety features are:

It extrapolates the Run-Flat concept of tyres. Even if the battery is not fully operational, the PBS-A device is capable of running the vehicle for several days.

In military, law enforcement, or private security vehicles, an additional function is included. In the event of a catastrophic failure or emergency situation, it adds an internal panic button, which will start the vehicle in a matter of moments without leaving the vehicle and ensure its operation (even if the chemical energy source is completely unusable).

Even if the factory battery fails, the device keeps the vehicle's electrical and electronic systems operational.

Detects anomalies prior to a failure or problem thanks to the constant monitoring of the vehicle's electrical and electronic parameters. Allows preventive maintenance before a breakdown occurs.

The PBS-A system can detect, thanks to parameter monitoring, whether the driver is driving properly.

Automatically cuts off the current at the PBS-A system terminals in case of an accident.

It is possible to limit the operation of the system from a control center in a certain period of time by a specific geographical area. If the vehicle attempts to leave the delimited area, the control center will shut down the system and the vehicle will stop operating.

Communication via smartphone is allowed in order to manually activate some functions of the PBS-A system, such as real-time parameter display or automatic vehicle locking.

As can be seen, the device combines its electronics and programming so that security is above everything else. There will be no more headaches for a battery in bad condition or unexpected failures. With PBS-A, your safety is guaranteed.

Available configurations

PBS-A device can be configured in different ways depending on the type of application it is develop for. Its versatility gives it an important feature in terms of configuration: Adaptability. The PBS-A adapts in size, current and intensity to any other system or energy source, fully improving the system. In order to better understand the range of configuration options, a number of specific uses of the PBS-A device will be explained for its most significant sectors of operation.

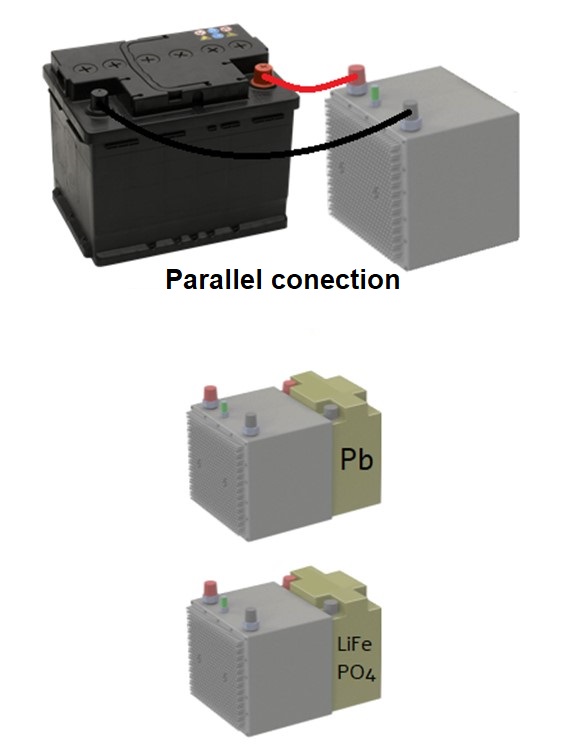

As far as the automotive sector, the PBS-A device can be configured for both traditional combustion vehicles and hybrids, 100% electric, hydrogen... without prejudice to the vehicle's other energy systems. In this case, the chosen configuration is to connect the PBS-A device parallel to the chemical battery of the vehicle. In addition to the energy advantages, it brings to the set the device can collect and monitor about 1 million data per minute thanks to the CAN bus.This allows the occupant to know all parameters in real time and to be inform of anomalies or malfunctions in his vehicle.

With regard to the industrial sector (machinery, vehicles or any other industrial energy system), the PBS-A device may be hybridised with any source of energy, even if it does not have conventional chemical batteries. This can bring significant advantages in relation to the energy management of an industrial facility. Energy saving is essential as long as it does not lead to malfunctioning or malfunctioning of machinery. The PBS-A device increases that savings because energy peaks come out more slowly. As a result, they are reduced and consequently, the power hired at the industrial facility is reduced.

Based on the efficient use of supercondensors and specific electronics for each specific case, the PBS-A device protects the circuits of the hybridised system and its own electronics and ensure proper operation with the appropriate characteristics, avoiding anomalies or incorrect actions. Therefore, the most appropriate configurations for this sector would be those that hybridize the PBS-A device (with a small lead battery or a lithium ferrophosphate battery, which would act as an auxiliary) with the energy source in at issue, properly adjusting and improving its properties.

Available configurations

PBS-A device can be configured in different ways depending on the type of application it is develop for. Its versatility gives it an important feature in terms of configuration: Adaptability. The PBS-A adapts in size, current and intensity to any other system or energy source, fully improving the system. In order to better understand the range of configuration options, a number of specific uses of the PBS-A device will be explained for its most significant sectors of operation.

As far as the automotive sector, el dispositivo PBS-A puede configurarse tanto para vehículos de combustión tradicionales como para híbridos, 100% eléctricos, hidrógeno… sin perjuicio alguno para los demás sistemas del vehículo. En este caso, the chosen configuration is to connect the PBS-A device parallel to the chemical battery of the vehicle. In addition to the energy advantages, it brings to the set the device can collect and monitor about 1 million data per minute thanks to the CAN bus.This allows the occupant to know all parameters in real time and to be inform of anomalies or malfunctions in his vehicle.

With regard to the industrial sector (machinery, vehicles or any other industrial energy system), the PBS-A device may be hybridised with any source of energy, even if it does not have conventional chemical batteries. This can bring significant advantages in relation to the energy management of an industrial facility. Energy saving is essential as long as it does not lead to malfunctioning or malfunctioning of machinery. The PBS-A device increases that savings because energy peaks come out more slowly. As a result, they are reduced and consequently, the power hired at the industrial facility is reduced.

Based on the efficient use of supercondensors and specific electronics for each specific case, the PBS-A device protects the circuits of the hybridised system and its own electronics y asegura un correcto funcionamiento con las características adecuadas, previniendo anomalías o actuaciones incorrectas. Por eso, the most appropriate configurations for this sector would be those that hybridize the PBS-A device (with a small lead battery or a lithium ferrophosphate battery, which would act as an auxiliary) with the energy source in at issue, properly adjusting and improving its properties.

2023 PBS-A Labs ©

Hybridization of energy systems

2023 PBS-A Labs ©

Hybridization of energy systems